Specialty Vehicles

Recreational vehicles, emergency vehicles, buses, and trains—specialty vehicle manufacturers need solutions that can handle a high degree of part variety. Explore why our solutions are game-changers in meeting the unique challenges of this dynamic industry.

State of the Industry

GROWING PAINS AND SURGING DEMAND

Supply chain complexity and disruptions slowing production of vehicles

Increasing capital costs and inflation, hindering investment in production

Global talent shortage impacting OEMs that require skilled labor

Surge in demand for typically low volume products with high-complexity

REVOLUTIONIZING VEHICLE PRODUCTION

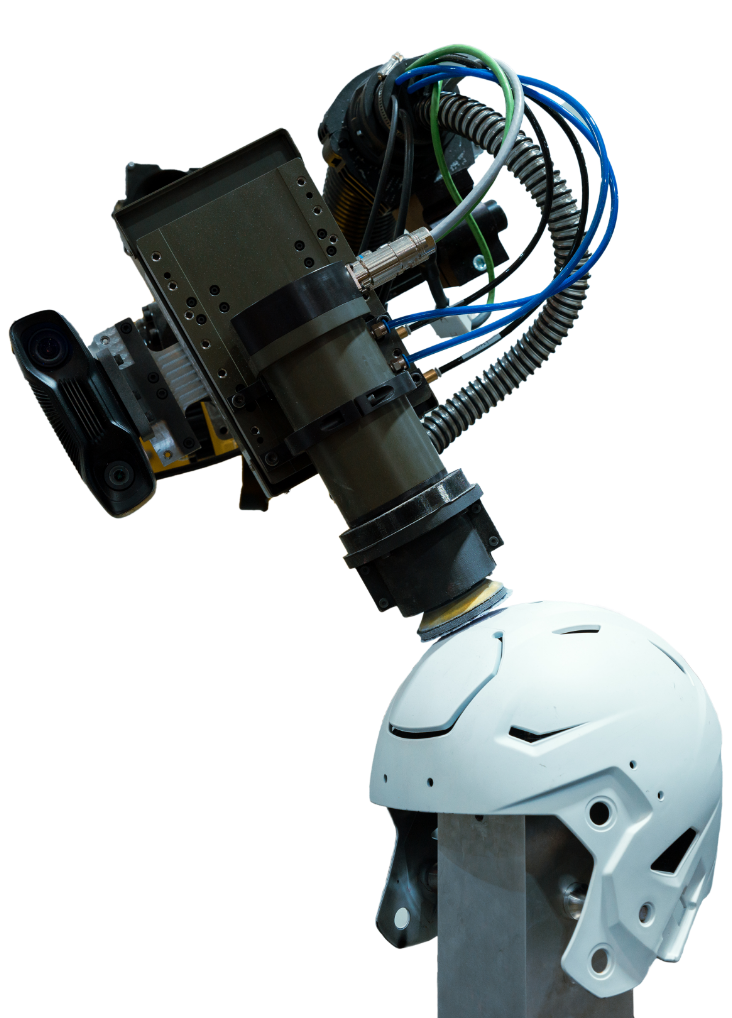

Specialty vehicle manufacturers produce a variety of parts ranging in variability and size. We enable them to meet growing demands for vehicles by removing barriers to scale and alleviating labor with our artificial intelligence and advanced robotics.

EFFICIENCY IMPROVEMENT

High annual labor turnover in surface finishing industries can cause delays in the production of vehicles. Our solutions help specialty vehicle manufacturers meet demand by reducing manual labor reliance and increasing capacity.

WASTE REDUCTION

Our solutions can slash material waste by 50%, now benefiting manufacturers dealing with diverse, lower volume parts that previously couldn’t justify automation due to technological and economic constraints.

IMPROVING WORKER LIVES

On average, we can reduce ergonomically challenging tasks by 90%. Workers can be trained to become robot operators in just 1 day. This upskilling helps them to advance in their careers and increase their earning potential.

ROBOTS ON DEMAND – AUTOMATION WITHOUT CAPEX

Instant Value

Risk-Free Adoption

Solution-Centric

Speedy Growth

ENABLING INDUSTRY LEADERS TO INNOVATE

BetterWay Products Inc. is the largest producer of fiberglass in the United States. They’re a leading supplier in the marine, RV, and specialty vehicles industry.

Request a demo