Robots Empowering Humans in Manufacturing: An Efficient and Productive Team

The Realities of the Manufacturing Workforce Shortage The biggest challenge U.S. manufacturers face today is an acute labor shortage. Competition for skilled workers is fierce, and the skills gap grows yearly. Here are some statistics that bring the manufacturing workforce shortage reality into focus: With consumers demanding more than ever, a manufacturer’s ability to consistently…

How Automated Surface Treatment Operations Impacts Worker Health, Environment, and National Security

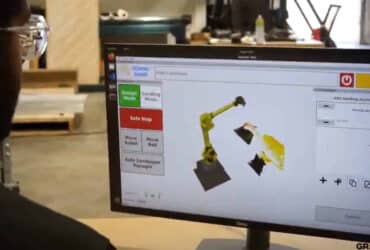

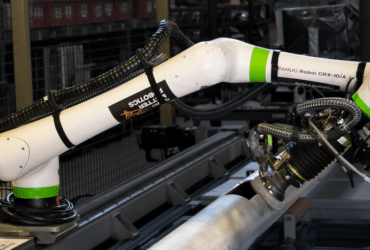

GrayMatter Robotics develops AI-powered smart robotic cells that help manufacturers remain competitive by increasing productivity, improving process consistency, eliminating waste, reducing ergonomically challenging work, compressing cycle times, and expanding production capacity. Our proprietary GMR-AI™ is physics-informed technology that powers our robotic cells to autonomously perform sanding, blasting, buffing, polishing, spraying, coating, trimming, and inspection for…

The Difference Between Robotic Cells for High-Mix Surface Finishing vs. Mass Production

Robotics for Mass Production Today Surface finishing robotics for mass production have been profitably deployed for a few decades. The following factors have contributed to the success of robots in mass-production applications: High-Mix Surface Finishing Requires Advanced AI Robotic cell requirements for high-mix surface finishing applications are different. Part changeover needs to happen in a…

How Smart Robotic Cells Powered by Physics-Informed AI are Advancing Manufacturing Applications

Over the last few years, data-driven artificial intelligence has delivered impressive results in applications such as recommendation engines (e.g., books and movies), playing games, facial recognition, text translation, text synthesis, and fraud detection. This type of AI uses vast data to train the system. In many applications, a large amount of data is readily available…

Advanced Prognostics and Health Management (PHM) Technology Enables Robot Deployment in High-Mix Manufacturing Applications

Many companies have tried to deploy robots in high-mix manufacturing applications. Unfortunately, most report disappointing results and believe robots are not feasible in high-mix environments. Problems may arise due to (1) the inability of the technology to deal with the part-to-part variability in an efficient manner or (2) long downtimes due to unscheduled maintenance and…

Built In Honors GrayMatter Robotics in Its Esteemed 2023 Best Places To Work Awards

GrayMatter Robotics Awarded One of the Best Places to Work in Los Angeles Los Angeles, CA, January 11, 2023 — Built In today announced that Gray Matter Robotics was honored in its 2023 Best Places To Work Awards. Specifically, GrayMatter earned a place on the Best Startups to Work list in Los Angeles. The annual…

Robots Need to Master Autonomous Tool Manipulation to Expand their Roles in Manufacturing

Many psychologists believe that humans’ ability to use complex tools makes them different from animals. Tools enable humans to overcome limitations in speed, reach, and force in manipulating or making value-added changes to objects. Using tools provides a way for humans to manipulate objects indirectly – humans manipulate tools, and tools manipulate objects. This mode…

Why Automation is Key to Innovation

We often see in news headlines that automation is a major threat to jobs and a potential enemy of our financial well-being. However, this narrative fails to acknowledge the value of automation in improving our lives. Automation is a major force behind many modern innovations and associated industries. Unfortunately, the connection between automation and innovation…

Don’t Overlook These Benefits When Calculating Your ROI on Automation

Automation, especially in robotics and AI, has many advantages for enterprise organizations implementing advanced technology into their daily operations. The benefits of automation include time to value, improved accuracy, reliability, productivity, scalability, and enhanced employee morale. But the benefits can be much more profound, might not be direct cost savings when calculating the ROI, and…

Five Strategies to Combat Manufacturing Labor Shortages

Many manufacturers struggle to find skilled labor for their manufacturing plants. According to the Society of Manufacturing Engineers, 89% of manufacturers are having difficulty finding workers in the United States today. Not only is the labor shortage impacting businesses’ ability to hire, but it’s also stunting businesses’ ability to grow and meet production demands. Manufacturers…

The Consequences of the Manufacturing Labor Shortage

The biggest challenge U.S. manufacturers face today is the acute labor shortage. Competition for skilled workers is fierce, and the skills gap grows yearly. A March 2022 survey from Deloitte predicts a shortage of more than two million U.S. manufacturing workers by 2030, potentially leading to an opportunity cost of $1 trillion per year if…

Automating Your Manufacturing Environment Without Sticker Shock

How Robots-as-a-Service (RaaS) Can Speed Time to Value While Lowering Expenses Is CapEx an Outdated Automation Model? Until recently, automating your manufacturing environment meant expensive upfront costs to acquire equipment, not including software, training, maintenance, and service fees (or the CapEx model). When companies use the CapEx model to purchase technology, they are then responsible…