The Realities of the Manufacturing Workforce Shortage

The biggest challenge U.S. manufacturers face today is an acute labor shortage. Competition for skilled workers is fierce, and the skills gap grows yearly. Here are some statistics that bring the manufacturing workforce shortage reality into focus:

-

- The Advanced Robotics for Manufacturing (ARM) Institute’s prediction is that 4.6 million manufacturing jobs will need to be filled in the United States over the next decade.

-

- The March 2022 survey from Deloitte predicts a shortage of more than two million U.S. manufacturing workers by 2030, potentially leading to an opportunity cost of $1 trillion annually.

-

- The National Association of Manufacturers (NAM) states that 71% of manufacturers find it increasingly harder to find skilled workers.

With consumers demanding more than ever, a manufacturer’s ability to consistently produce affordable, high-quality products for on-time delivery is vital to maintaining a competitive edge. For many operations, however, this benchmark is increasingly challenging to meet and is prompting manufacturers to take strategic action through automation to meet their operational goals.

Robotics Automation is a Solution, But Not One-Size-Fits-All

Turning to robotics as a solution to the labor shortage is an obvious approach in manufacturing, but many applications require new, innovative robotics solutions. For example, traditional robotics technology deployed in mass-production applications does not work for high-mix applications. These applications require frequent part changes and present many part variabilities, so manually programming robots is not an economically viable option in these circumstances.

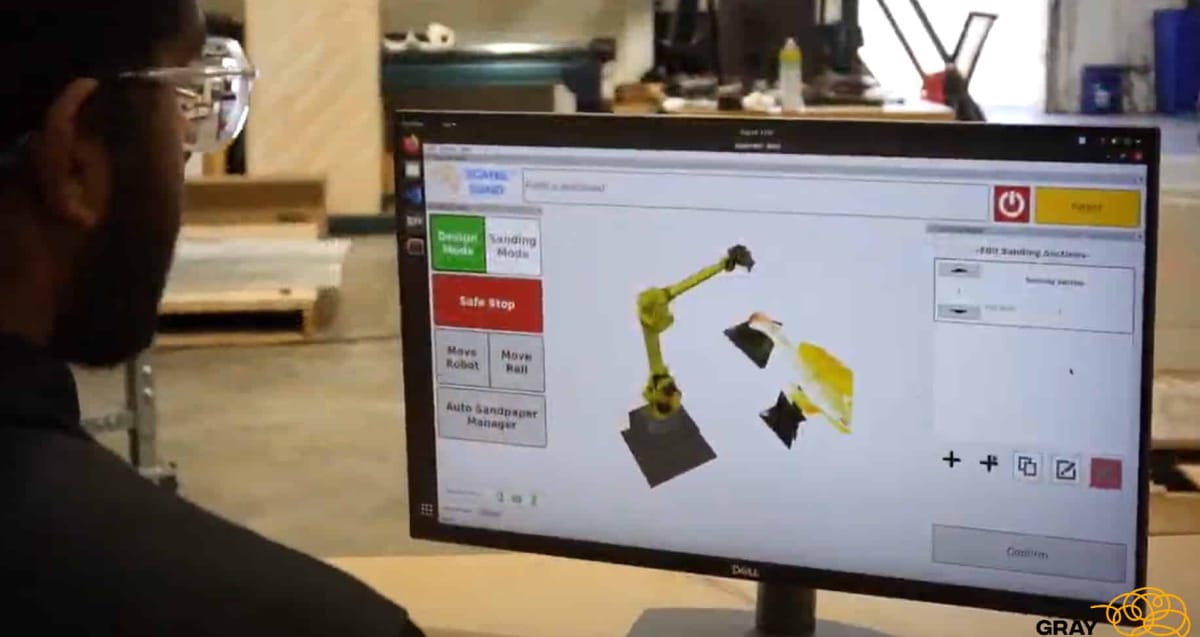

Now, smart robotic cells that program themselves from high-level task descriptions are an affordable option. But, these technologies must deliver highly efficient performance to be economically viable and provide safety assurance to prevent damage to the parts and tools. To address these challenges, we have developed advanced AI technology (GMR-AI™) to power robotic cells for surface treatment in high-mix manufacturing applications.

We can’t overlook the human factor when creating future smart factories. Today many workers perform physically demanding and unsafe tasks in these environments, posing health risks and low career advancement opportunities. We’re building smart robot cells that can work at a superhuman performance level and empower workers rather than replace them. We’ve proven that smart robotic cells can significantly improve workforce productivity, reduce health risks and provide a competitive edge to manufacturers. In addition, managing and operating robotic cells by existing workers enable career advancement, more significant work satisfaction, higher retention, and less turnover.

Powering the Smart Factory with Physics-Informed AI

Recently, data-driven AI has delivered impressive results in applications such as recommendation engines, games, face recognition, text translation, fraud detection, and text synthesis. Unfortunately, a purely data-driven approach for AI is not a scalable model in manufacturing applications. And collecting high-quality data takes significant time and usually incurs high costs. Manufacturing has many known models and process knowledge, and rediscovering these models and knowledge through a purely data-driven approach does not make sense.

On the other hand, all known models make simplifying assumptions to reduce complexity and therefore are approximate. We need AI that exploits the known models and uses a data-driven approach to augment the models. Physics-informed AI enforces known physics as a constraint in the AI system. On the one hand, this approach restricts the solution space making the problem much more tractable. On the other hand, this requires significantly more complex representations and associated solution generation methods to handle complex constraints to produce acceptable computational performance. We have made fundamental advances in physics-informed AI to support the robotic automation of processing applications.

These AI-powered smart robotic cells help manufacturers remain competitive by increasing productivity, improving process consistency, eliminating waste, reducing ergonomically challenging work, compressing cycle times, and expanding production capacity. Our proprietary GMR-AI™ technology powers our robotic cells to autonomously perform sanding, blasting, buffing, polishing, spraying, coating, trimming, and inspection for high-mix manufacturers. Our solutions are used by aerospace and defense, specialty vehicles, maritime, metal fabrication, interior and architectural components, recreation and consumer products, and general manufacturing industries.

Smart robotic cells are truly complex cyber-physical systems, but generating safe and efficient solutions depends upon achieving tight integration among perception, planning, control, and learning components. We’ve built a solutions framework that enables communication across various components at appropriate bandwidth. This allows each component to use our GMR-AI™ to make high-quality decisions adapting to each component to achieve optimal system-level performance. Our technology also performs smart prognostics and health management of the robotic cell, proactively preventing the system from entering into error states. This allows us to achieve a highly resilient system that quickly recovers from errors and therefore minimizes downtime.

Risk-Free, Affordable Smart Robotic Cells for Surface Treatment

We’ve adopted the Robots-as-a-Service (RaaS) model, which dramatically helps to reduce our customers’ upfront financial costs, and replaces the traditional CapEx model. For example, similar to a SaaS model, you’d pay a monthly subscription fee if you’re interested in deploying a robotics automation solution. With the RaaS model, however, this fee covers the hardware, software, maintenance, support, updates, and upgrades. This means you can see the time to value immediately. Because we own the hardware and software, we also take the burden off the customer regarding technology obsolescence since upgrades are included. It’s our responsibility to ensure that your deployed solution delivers the performance we promise.

Robots and Humans: A Powerful Team that Empowers People

While robots are becoming more advanced and capable of performing a wider range of tasks, there are still many reasons why they will only partially replace humans in manufacturing automation. Here are a few key reasons:

-

- Flexibility: While robots excel at performing routine tasks with high precision, they are not as adaptable as humans. In manufacturing, there are often unexpected changes to the production process, or new products often require adjustments on the fly. Humans are better suited to handle these changes and adapt to new situations quickly.

-

- Creativity and problem-solving: Robots can program themselves to perform specific tasks, but (at least today) they lack humans’ creativity and problem-solving skills. When unexpected issues arise, humans are better equipped to devise creative solutions to solve them.

-

- Complex decision-making: In manufacturing, complex decisions need to be made that require a human touch. For example, regarding quality control, today, humans are better equipped to make subjective judgments about whether a product meets specific standards.

-

- Human touch: Some manufacturing processes require a human touch, such as the final surface finishing of delicate or intricate parts. In these cases, humans are better suited to handle these tasks and ensure that the final product meets the desired specifications.

While robots are essential to manufacturing automation, they are not replacements for human workers. Combining robots and human workers can create a powerful and highly productive manufacturing process. It’s our vision to empower workers and improve their quality of life by simplifying, accelerating, and automating the tedious and ergonomically challenging tasks of surface treatment for manufacturing.

To see our GrayMatter solutions in action, visit our YouTube channel.